LTL Blog

Lineman's Testing Laboratories of Canada

Stay Safe: Do Not Share...

Is There a Difference B...

6 Steps for Proper Ele...

Ensuring Electrical Sa...

Are you compliant?

Transformer failure is real. The cost to the owner is significant and includes loss of equipment, production, potential hike in insurance premiums, MOL fines, but more importantly, the potential for worker injury or worse, fatality.

Exercise due Diligence: Know your personal and business obligation and liability

Employers are required by clause 25(2)(h) of the Occupational Health and Safety Act (OHSA) to take every precaution reasonable in the circumstances to protect workers. In this respect, employers should refer to, among other things, accepted industry standards such as the current editions of the EUSA Rulebook and the Ontario Electrical Safety Code in determining what precautions are reasonable when working around electricity.

Ensure the contractors you hire to manage your electrical system have adequate insurance, qualified in-house engineers and licensed and competent technicians for the electrical services being performed. The owner and the company employees involved in the hiring of the contractor will be held liable in the event of an incident where a worker is injured.

Employing certified and experienced technicians, LTL will partner with you to ensure you are compliant from start to finish. LTL offers:

- Engineering studies

- Drawings

- Equipment labeling

- Upgrades and repairs to non-compliant equipment

- Arc blast certification training

- PPE training – care and use

- PPE supply

- Work Programs – compliance policies and procedures to meet MOL requirements

With the challenges presented by COVID-19, it’s important to ensure your electrical system is running at optimum efficiency and that any current system issues are identified and addressed before system failure. LTL will ensure your electrical system can support your production requirements to keep your business up and running.

Regular preventative substation maintenance addresses liability and equipment operations with the following key benefits:

- Minimizes production downtime, pain and stress

- Avoids associated costs and penalties for loss of production

- Mitigates liability and responsibility (owner or tenant)

- Addresses legal requirement to maintain and prove system compliance

- Ensures current drawings of electrical equipment are posted and workers are provided with the required safety equipment

- Protects your workers

- Extends the life of your equipment

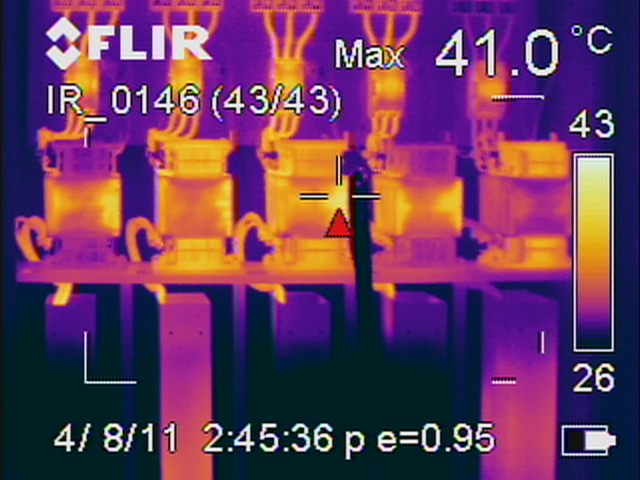

Why is Infrared Scanning important?

Infrared Scanning is proven. It works. No outage – no downtime. It is a very cost-effective and painless preventative maintenance service that identifies hot spots prior to the complete annual substation maintenance program. Performing your IR scan in advance of your substation maintenance allows for any issues identified to be addressed at the time of the substation maintenance.

Infrared Scanning identifies heat which increases resistance and decreases efficiency causing potential electrical equipment problems such as faulty connections, poor contacts, phase imbalances and overload conditions requiring immediate attention. The IR scan allows for repairs before failure or damage occurs.

LTL recommends IR scanning twice a year for all electrical equipment to ensure system reliability and continuous operation. IR scanning is very effective when performed by technicians who have the experience and knowledge to correctly identify and interpret the thermal information to provide the customer with accurate risk level results to properly address steps to correct any deficiencies prior to failure.

Do you know the importance of using licensed technicians in Infrared Scanning?

The credentials of the technician determine the quality and accuracy of the survey. Using a licensed electrician is key. LTL crews include staff who are fully certified in IR scanning, licensed electricians, and technicians with qualifications and expertise to conduct full and proper inspections of all electrical equipment. As our technicians also perform the repairs, their interpretation of the results is invaluable and effective.

Equipped and protected with the proper arc flash safety gear (thereby removing liability from our customer), our electricians open required panels allowing for accurate identification of hot spot locations through internal imaging.

Please contact your local LTL Sales Representative for additional information on our compliant programs or with any questions or concerns you may have.

Your comment will go through an approval process and may not be visible to the public right away.